TV Shape Sapphire Optical prism| For Rectangular Display Modules & Precision Instruments

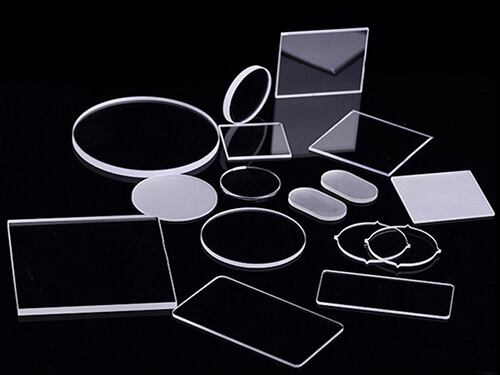

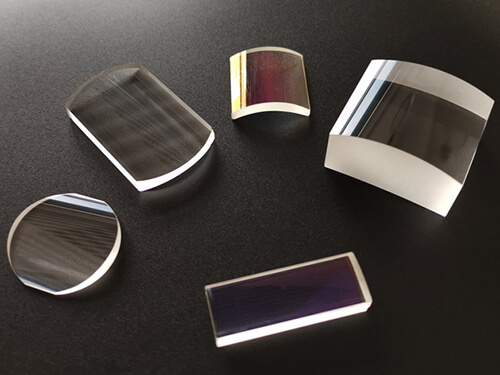

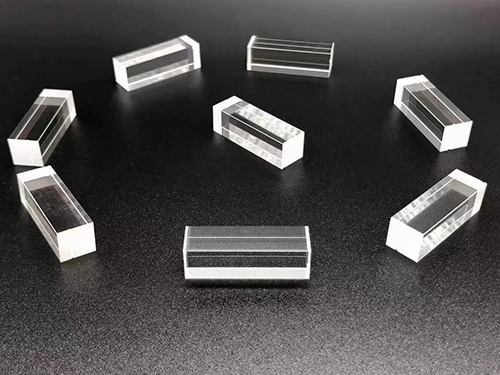

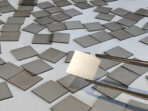

This TV-shaped sapphire crystal is designed for integration into rectangular display modules and watch cases, where curved corners and straight-edge symmetry are required. Made from high-purity monocrystalline sapphire, it offers high optical clarity, extreme surface hardness, and superior resistance to abrasion and chemical exposure.

The geometry supports edge-to-edge mounting, making it ideal for wearable devices, smart displays, and precision optics that deviate from traditional round or square designs. Available with AR, AF, and DLC coatings, the crystal maintains >90% light transmission while meeting ISO9001 and RoHS standards. Sizes and thicknesses are fully customizable. Each unit is finished with precise edge control to ensure proper alignment and sealing within complex enclosures.

Share:

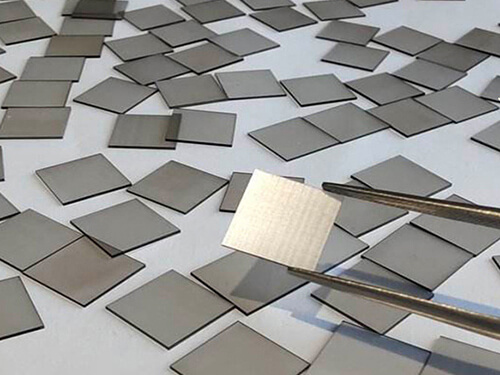

The TV-shaped sapphire crystal is manufactured for precision fitment in non-standard rectangular enclosures, especially those with rounded corners and straight sides. Each unit is processed with strict flatness control, consistent coating thickness, and customizable dimensions to meet integration requirements for display modules, smart devices, and specialty optics.

| Specification | Details |

|---|---|

| Material | Monocrystalline Sapphire (Al₂O₃ ≥ 99.99%) |

| Shape | TV Shape (Rectangular with rounded corners) |

| Dimension Range | 18×12 mm – 50×40 mm (customizable by request) |

| Thickness Range | 0.3 mm – 2.5 mm |

| Hardness | HV700 – HV1800 |

| Light Transmittance | >90% (Visible Spectrum, uncoated) |

| Edge Finish | Polished / Micro-Chamfered / Fully Rounded |

| Surface Coatings | AR / AF / ITO / UV / DLC (optional single or dual side) |

| Marking Options | Laser Engraving / Screen Printing / Electroplating |

| Tolerance | ±0.02 mm – ±0.10 mm (depends on edge spec) |

| Packaging | Anti-static tray + multilayer export carton |

| Certifications | ISO9001 / BSCI / RoHS |

| Lead Time | 5–15 days (standard) / 20–45 days (custom with coating) |

Custom tooling is available for unconventional corner radii or inner cutouts—please specify during inquiry to avoid secondary modification.

The TV-shaped sapphire crystal is purpose-built for devices with rectangular or rounded-corner display zones—such as wearable displays, retro-style wristwatches, and embedded sensor modules. Unlike traditional square or circular formats, the TV shape supports edge-to-edge designs while maintaining geometric symmetry, making it suitable for both aesthetic and functional integrations.

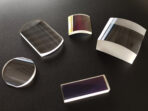

⚙️ Functional Advantages

-

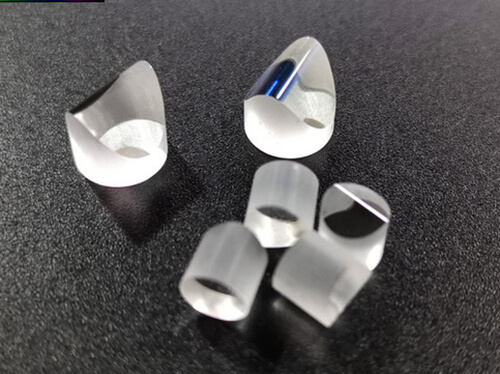

Shape Precision: Corners are processed with consistent radii to fit enclosures with matched edge profiles, avoiding stress concentration.

-

Edge Configuration: Options include full polish, matte edge, or chamfered finish to accommodate bezel-fit, adhesive bonding, or press-fit applications.

-

Multi-Coating Support: Depending on functional needs, the surface can receive AR (anti-reflective), AF (anti-fingerprint), ITO (conductive), or DLC (wear-resistant) coatings—each tested for adhesion, uniformity, and durability.

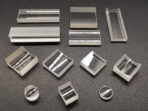

🧪 Material and Optical Properties

Sapphire’s intrinsic hardness (HV700–1800) ensures superior resistance to abrasion and pressure. With >90% visible light transmittance and excellent UV stability, the material remains optically clear under prolonged exposure. Custom thicknesses help balance durability and display brightness.

Example: A 1.0 mm thick crystal with AR coating on both sides maintains 92% transmittance while surviving >300N surface pressure and 50°C thermal cycling.

📋 Compliance & Traceability

Each unit can be supplied with full dimensional inspection reports, coating validation, and material certificates upon request. The product meets ISO9001 manufacturing standards and complies with RoHS and BSCI directives, ensuring global supply chain compatibility.

▍Rectangular Smartwatches

TV-shaped sapphire crystals are often used in rectangular smartwatch designs, especially those mimicking a “retro TV” style form factor. Their edge-to-edge geometry enables full display coverage while maintaining bezel symmetry and resistance to scratching from daily wear.

▍Medical & Diagnostic Displays

In diagnostic hand-held equipment or wearable patient monitors, these crystals are used as transparent protective covers. Their chemical resistance and clarity ensure durability under repeated disinfection and long operating hours.

▍Optical Measurement Windows

Industrial sensors or portable spectrometers that require flat yet wide-angle optical windows use TV-shaped sapphire to maximize active area while ensuring a low distortion path for signals or laser beams.

▍Automotive Dashboard Instruments

High-end automotive dashboards or center control units sometimes adopt non-standard rectangular touch interfaces. TV-shape sapphire is applied as a top lens layer to improve longevity and maintain clarity under constant light exposure and vibration.

▍Luxury Watch Concepts & Niche Brands

Independent watchmakers experimenting with unconventional case geometries—such as elongated or retro-styled displays—often specify TV-shape sapphire crystals to maintain case uniformity without compromising on material integrity.

Q1: What defines a "TV Shape" in sapphire crystals, and how is it different from square or rectangular formats?

TV shape refers to a rectangle with rounded corners and soft edge transitions—similar to vintage television screens or modern rectangular wearables.

It differs from a strict rectangle by eliminating sharp 90° corners, reducing stress concentrations during press-fit or bonded installations.

Q2: Can I specify a custom radius for the corners?

Yes. Corner radius (R) can be specified separately from the width and height. Standard values range from R0.5 mm to R5 mm depending on total size.

💡 For adhesive bonding, radii ≥1 mm are recommended to prevent corner peel during thermal expansion.

CAD drawing or sample reference is required for non-standard transitions (e.g., asymmetric top/bottom curves).

Q3: Are AR or DLC coatings compatible with the TV shape geometry?

They are. Coatings are applied via vacuum deposition and can cover flat or slightly domed surfaces uniformly.

-

AR (Anti-Reflective) reduces glare and boosts display readability.

-

DLC (Diamond-Like Carbon) enhances scratch resistance in rugged environments.

⚠️ Note: Coating is typically applied to one side—ensure installation orientation matches.

Q4: What’s the best bonding method for integrating this crystal into a display module?

UV-curable adhesives are most commonly used, allowing precise edge sealing without adding mechanical fasteners.

-

For smart devices, light-blocking ink borders (printed on inner face) are often added to conceal adhesive tracks.

-

For pressure-sealed modules, micro-gaskets with TV-shaped profiles are also available.

Q5: Is there a minimum order quantity (MOQ) for custom sizes?

No fixed MOQ for engineering samples—small runs of 20–30 pcs are accepted.

Bulk orders (200+ pcs) benefit from lower unit cost and faster repeat production.

For samples with custom coatings or printed borders, lead time is typically 20–30 working days.

Q6: Can the crystal be laser-drilled for sensor holes or logo marks?

Yes, but hole placement must maintain minimum spacing from edges (≥1.5× thickness).

Example: For a 1.0 mm thick crystal, hole center should be ≥1.5 mm from any edge or corner arc.

All laser-cut features are post-annealed and inspected for micro-cracks.

Q7: What’s included in the shipment for custom production?

-

Dimensional inspection report (per batch)

-

Coating conformity certificate (if applicable)

-

RoHS declaration

-

Visual packaging photo (for shipping verification)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)