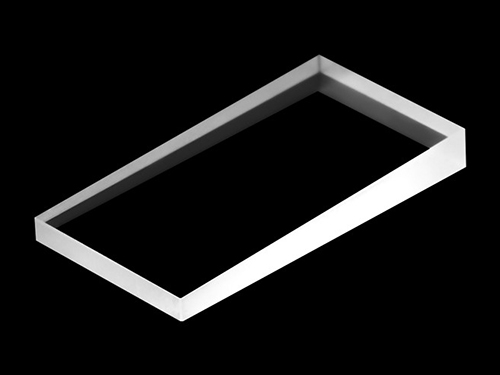

Square Sapphire Watch Crystal | Custom Fit for Watches & Wearables

Manufactured from high-purity monocrystalline sapphire, this square-shaped crystal is built for devices requiring high mechanical strength, clarity, and abrasion resistance. The square profile allows precise integration into non-circular watch cases, display modules, and optical enclosures where round lenses are not viable.

Available in various sizes and thicknesses, the crystal supports multiple surface treatments—including AR, AF, and DLC coatings—for enhanced optical and functional performance. Whether bonded, clamped, or framed, each unit is manufactured with tight tolerances and is tested to meet ISO9001 and RoHS requirements for international supply chains.

Share:

The Square Sapphire Watch Crystal is available in a wide range of dimensions and treatments to accommodate varying design and performance requirements. Each unit is manufactured to strict tolerances and undergoes multi-point inspection for clarity, flatness, and edge integrity. The following specifications reflect standard ranges, with custom values available upon request.

| Specification | Details |

|---|---|

| Material | Monocrystalline Sapphire (Al₂O₃ ≥ 99.99%) |

| Shape | Square (Flat / Slightly Domed options) |

| Dimension Range | 10×10 mm – 50×50 mm (customizable in 0.1 mm increments) |

| Thickness Range | 0.3 mm – 3.0 mm |

| Hardness | HV700 – HV1800 |

| Light Transmittance | >90% (Visible Light Spectrum) |

| Edge Processing | Polished / Chamfered / Beveled / Micro-Rounded |

| Surface Coating | AR / AF / ITO / UV / DLC (optional) |

| Printing Options | Laser Engraving / Screen Printing / Electroplating |

| Dimensional Tolerance | ±0.02 mm – ±0.10 mm |

| Packaging | Anti-scratch tray + moisture-resistant export carton |

| Certifications | ISO9001 / BSCI / RoHS |

| Lead Time | 5–15 days (standard) / 20–45 days (custom orders) |

Every unit can be shipped with a full inspection report upon request, including dimensional scan, optical transmittance test, and coating uniformity validation.

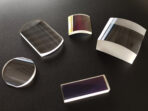

The square sapphire crystal is engineered for integration into timepieces and instrumentation that require sharp-edged geometry and robust optical protection. Its square profile—unlike standard round designs—supports flush mounting within rectangular watch cases, display panels, or precision sensor housings. Each crystal is manufactured from monocrystalline sapphire grown through the Kyropoulos or Verneuil method, ensuring optical purity and crystalline consistency.

What sets this crystal apart is its mechanical resilience: with a hardness up to HV1800, it resists abrasion far beyond mineral glass or hardened plastics. Optional coatings like AR (anti-reflective), AF (anti-fingerprint), and DLC (diamond-like carbon) improve durability in specialized environments. Surface treatments such as screen printing or laser marking are available for branding or functional overlay.

🔧 Integration & Compatibility Notes

-

Edge Geometry can be polished flat, chamfered, or micro-rounded to fit tight bezel tolerances.

-

Dimensional Tuning down to ±0.02 mm ensures no light leakage or gasket stress.

-

Bonding Options include UV-curing adhesives, metal compression frames, and gasket-sealed enclosures.

📋 Quality & Certification

Each batch undergoes full dimensional inspection and random optical transmittance tests. Coated parts are tested for adhesion (cross-hatch), wear (abrasion wheel), and environmental aging (salt spray, UV exposure). All manufacturing conforms to ISO9001:2015 protocols, and materials comply with RoHS and BSCI guidelines.

▍Wristwatch Assemblies

Square sapphire crystals are widely used in fashion and luxury watches that feature square or rectangular cases. These designs often require tight corner tolerances and uniform edge polishing to maintain bezel symmetry and water resistance.

▍Smartwatches & Wearable Devices

Smartwatch brands seeking distinctive form factors—especially those with square screens—use sapphire crystals to enhance scratch resistance and screen longevity. This is particularly common in sport-focused or premium models where impact exposure is higher.

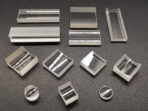

▍Display Covers for Optical Modules

Optoelectronic modules, such as barcode scanners, rangefinders, and biometric sensors, often employ square sapphire covers to ensure protection without distorting signal paths. Coated variants improve anti-reflection in high-illumination environments.

▍Industrial & Laboratory Equipment

Instrumentation panels, embedded sensors, and control devices operating in corrosive or abrasive settings benefit from the chemical inertness and optical clarity of square sapphire windows—especially when integrated flush into metal housings.

▍Aerospace & Military Applications

High-durability square crystals are used in cockpit instruments, ruggedized enclosures, and tactical field devices where traditional glass would fail under thermal or impact stress. Sapphire's low thermal expansion supports stable optical alignment.

Q1: What’s the typical difference between square and round sapphire crystals in watchmaking?

A: Square crystals allow for precise edge alignment in non-circular designs, such as rectangular or tonneau-shaped watches. They require tighter corner polishing and offer less stress distribution compared to round crystals, making dimensional control even more critical.

Q2: Can I request a custom size and still get AR or DLC coating?

Yes. Custom sizes (e.g., 36×36 mm, 42.5×45 mm, etc.) can be processed with AR, AF, UV, or DLC coatings as long as you specify coating side, coating type, and performance target (e.g. single-sided reflection <1%, or wear resistance >10N). Coating uniformity is validated during inspection.

💡 Tip: If your design uses optical sensors, request AR coating on the inner side to avoid glare interference.

Q3: Are all square sapphire crystals completely transparent?

While most are clear, options exist for smoked, tinted, or laser-treated surfaces. You can also specify a frosted or matte finish for privacy screens or semi-obscured display modules.

Q4: Will square crystals work with standard round sealing gaskets?

No. Square crystals require custom-shaped or laser-cut gaskets. Off-the-shelf round seals may not ensure consistent pressure along corners, leading to water ingress or stress cracks over time.

📌 Always request matching gasket specs if you're planning IP-rated enclosures.

Q5: What’s the minimum order quantity for custom square crystals?

There is no fixed MOQ for sampling. Prototype orders as small as 10–20 pcs are accepted, though coating, printing, and polishing options may influence unit price. Bulk pricing tiers start around 200 pcs.

Q6: What documents are included with the shipment?

Standard shipments include dimensional inspection reports, material certification, and packaging list. On request, we can also provide coating adhesion test results, RoHS compliance declaration, and optical transmittance graphs.

Q7: Can square sapphire be laser-cut with internal shapes (e.g. sensor holes)?

Yes, but hole or slot placement must follow minimum edge distance rules (typically ≥1.5× thickness) to avoid crack propagation. Tolerances on laser-cut features are usually ±0.05 mm unless otherwise specified.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)