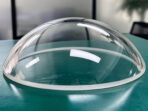

Custom Contour Sapphire Watch Crystal | Irregular Geometry Applications

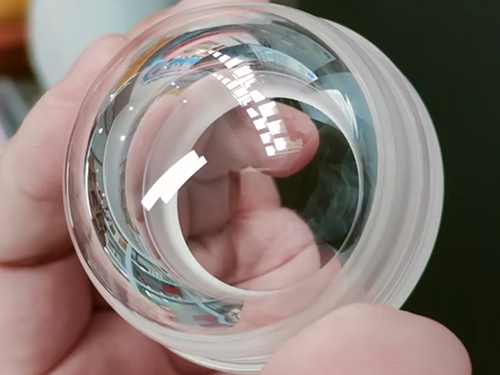

This custom contour sapphire crystal is manufactured for use in watch cases and optical devices requiring irregular shapes, non-standard outlines, or asymmetric edge profiles. Its geometry is defined entirely by client-supplied CAD, enabling seamless integration into designs that circular, square, or TV-shaped formats cannot accommodate.

Each crystal is CNC-profiled with sub-millimeter accuracy and available with optional coatings such as AR, AF, or DLC. Whether used in luxury watches, wearable electronics, or instrument windows, the contour fit ensures mechanical reliability without sacrificing optical clarity. The material offers hardness ratings up to HV1800 and >90% visible light transmittance. Dimensional tolerances as tight as ±0.02 mm are achievable depending on edge complexity.

Share:

The custom contour sapphire crystal is fully CNC-profiled based on customer-supplied drawings or samples. Each unit is fabricated using high-purity sapphire and optimized for edge complexity, bonding accuracy, and coating compatibility. Suitable for non-standard bezel designs, asymmetric wearable housings, or precision optical covers.

| Specification | Details |

|---|---|

| Material | Monocrystalline Sapphire (Al₂O₃ ≥ 99.99%) |

| Geometry | Custom Contour / Irregular Outline (per client CAD) |

| Size Range | Up to 60 × 60 mm (depends on contour complexity) |

| Thickness Range | 0.3 mm – 2.5 mm |

| Hardness | HV700 – HV1800 |

| Light Transmittance | >90% (Visible Light Spectrum, uncoated) |

| Edge Finish | CNC-polished / Chamfered / Micro-rounded |

| Tolerance | ±0.02 mm – ±0.10 mm (geometry-dependent) |

| Coating Options | AR / AF / UV / ITO / DLC (one- or two-sided) |

| Marking Options | Laser engraving / Screen printing / Electroplated logo |

| Packaging | Anti-scratch tray + moisture-protected export carton |

| Certifications | ISO9001 / RoHS / BSCI |

| Lead Time | 5–15 days (standard) / 20–45 days (custom tooling or coating) |

Complex outlines with internal cutouts, stepped edges, or multi-radius profiles may require tooling validation prior to mass production.

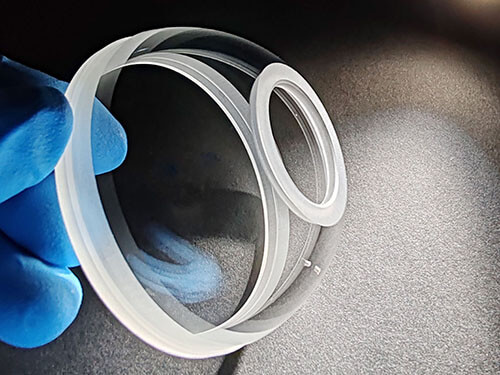

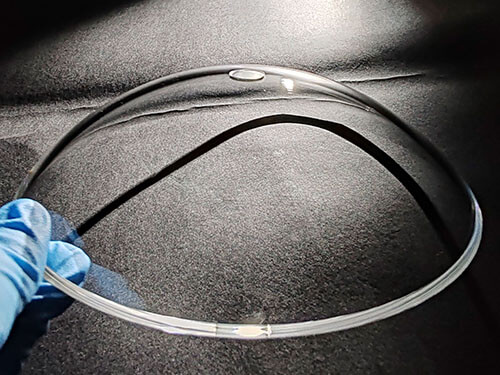

The Custom Contour Sapphire Crystal is developed for highly specific watch case designs and optical applications where standard geometries like round, square, or rectangular fail to provide proper sealing, alignment, or mechanical fit. It is manufactured via CNC profiling using DXF, STEP, or 2D CAD files supplied by the client, ensuring edge profiles match the housing with sub-0.05 mm repeatability.

🧭 Why Use Contoured Sapphire?

-

Uncommon Housing Shapes: For example, tonneau, hexagonal, oblong, asymmetric, or beveled-edge devices.

-

Display Modules with Cutouts: Where sensors, cameras, or indicator lights need precision clearance.

-

Mechanical Watches with Legacy Styling: Vintage-case restorations or one-off bespoke casings.

🔧 Fabrication Capabilities

-

CNC diamond cutting + fine grinding + edge polishing for multi-curve or stepped perimeters

-

Internal notches or side window tapers possible on request

-

Edge angles can be customized to support flush, raised, or recessed installation modes

-

Thickness variance per region (e.g., central dome + thinner edge rim) is available for weight optimization

📏 Example Applications & Configurations

Case 1: A luxury Swiss brand submitted a 42.7 × 39.4 mm irregular trapezoidal lens with curved edges and 1.2 mm corner fillets. Tolerance request was ±0.03 mm and AR coating only on the inner face.

Case 2: A wearable health tech device integrated a contoured sapphire window with two sensor holes and black masking print around edges.

Each unit is verified against the client’s CAD reference or functional gauge, and edge polishing follows functional requirements (optical seal, ultrasonic welding, or gasket compression).

▍Bespoke & Boutique Watchmaking

Independent and luxury watch brands often design unique case shapes—tonneau, cushion, asymmetric, or stepped-bezel formats. These require non-standard crystals that match edge-to-edge, ensuring water resistance and visual alignment without the limitations of off-the-shelf geometries.

▍Wearable Electronics & Medical Devices

Health monitors, glucose trackers, and next-gen fitness wearables may feature housings that follow body curves or integrate multiple sensors. Custom contour sapphire allows display coverage plus laser-cut holes or internal notches for photodiodes, ECG pads, or ambient light sensors.

▍Aerospace & Tactical Optics

Ruggedized control panels, cockpit interfaces, and embedded optical assemblies often use contoured sapphire to protect high-value components. The geometry may follow a control surface, integrate a cut-out for a joystick or camera lens, or require coating only on a defined region.

▍Embedded Industrial Modules

Automation terminals and sensor modules built into production machinery sometimes require transparent but shaped covers—e.g., with beveled edges to avoid mechanical snag, or rounded sidewalls for recessed fitment. Sapphire provides chemical resistance and optical clarity under vibration and dust.

▍Restoration Projects or OEM Reverse Engineering

In some cases, sapphire crystals are fabricated to match discontinued legacy casings or to reverse engineer a part for which no CAD exists. 3D scanning data or physical samples can be used to replicate the original contour.

Q1: What defines a "custom contour" sapphire crystal?

A: It refers to any crystal shape that deviates from standard round, square, or TV profiles. This includes oblong, irregular polygon, curved asymmetric, notched, stepped, or hybrid edge outlines based on precise CAD files.

Geometry is fully determined by the client drawing or sample—no fixed templates.

Q2: What file format is required to start a custom design?

We accept .DXF, .DWG, .STEP, or .IGS formats. If no file is available, a physical sample can be 3D scanned.

For best accuracy:

– Include a fully dimensioned 2D projection.

– Specify coating zones (e.g., AR only on viewing window).

Q3: Can internal holes or cutouts be added?

Yes. Through-holes, slots, or recesses can be CNC- or laser-machined.

-

Minimum spacing from edges should be ≥1.5× thickness.

-

Tolerances on cut features typically range ±0.05 mm.

Example: A 1.2 mm thick crystal can safely accommodate a Ø3 mm camera hole with 2 mm spacing to nearest edge.

Q4: Are coatings compatible with irregular shapes?

All standard coatings (AR, AF, UV, ITO, DLC) are compatible.

-

For full-surface coverage, masking follows contour edge.

-

For partial coatings, specify clear zones and side.

⚠️ Confirm orientation before bonding—coated side may vary.

Q5: What’s the typical lead time for first orders?

-

Without coating: 12–20 business days

-

With coating or printing: 20–35 business days

-

Tooling for very complex geometries may add 3–5 days

Small-volume prototypes (10–30 pcs) are supported with full QA.

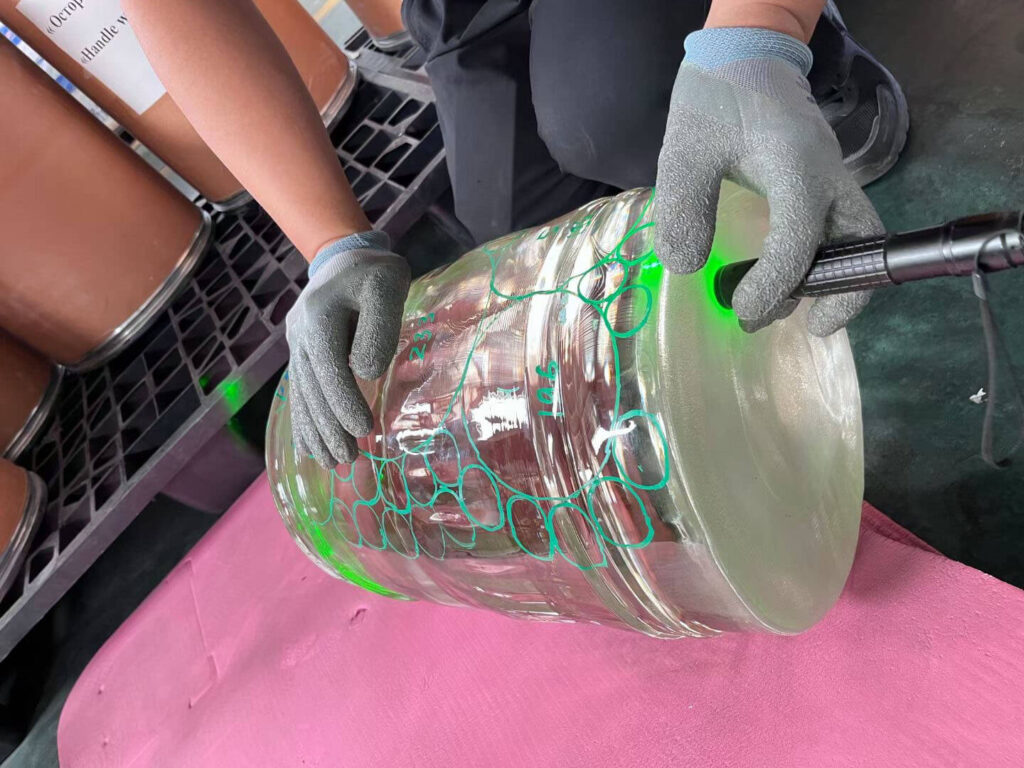

Q6: What’s included in the quality inspection?

-

Dimensional verification vs CAD (edge-to-edge / radius / hole alignment)

-

Flatness test

-

Coating adhesion test (if applicable)

-

Cosmetic inspection for edge chips, inclusions, or surface haze

Optional: Coating transmission graph, RoHS compliance sheet

Q7: Can I reorder a shape later without resubmitting CAD?

Yes. All approved contours are archived with unique part codes.

Reorders can skip tooling phase unless modifications are made.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)